Demonstrating energy intensive industry-integrated solutions to produce liquid renewable energy carriers from captured carbon emissions

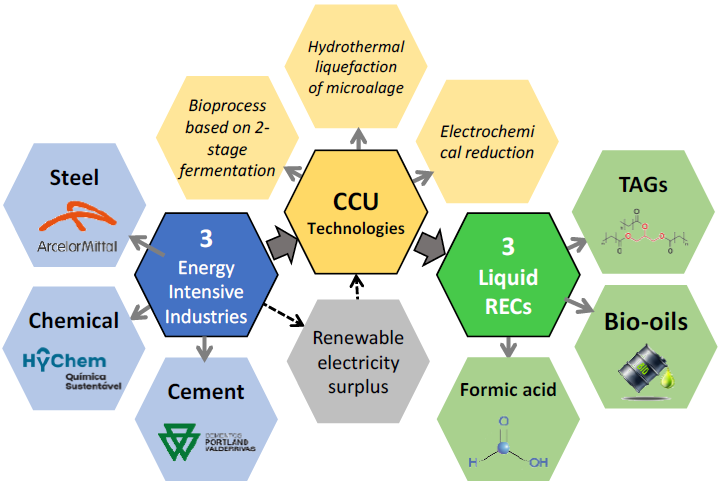

Currently, there is an increasing trend in the implementation of CCUS projects in Europe, as a solution to mitigate GHG emissions from energy intensive industries (EIIs). In CAPTUS, the focus is on the production of liquid energy carriers from industrial flue gas dealing with low CO2 fractions and addressing also for the first time the optimal integration with renewable electricity surplus to reduce the increasingly renewable curtailments. CAPTUS will provide an industrial roadmap to a net-zero carbon future through EII-integrated solutions from captured carbon emissions.

Currently, there is an increasing trend in the implementation of CCUS projects in Europe, as a solution to mitigate GHG emissions from energy intensive industries (EIIs). In CAPTUS, the focus is on the production of liquid energy carriers from industrial flue gas dealing with low CO2 fractions and addressing also for the first time the optimal integration with renewable electricity surplus to reduce the increasingly renewable curtailments. CAPTUS will provide an industrial roadmap to a net-zero carbon future through EII-integrated solutions from captured carbon emissions.

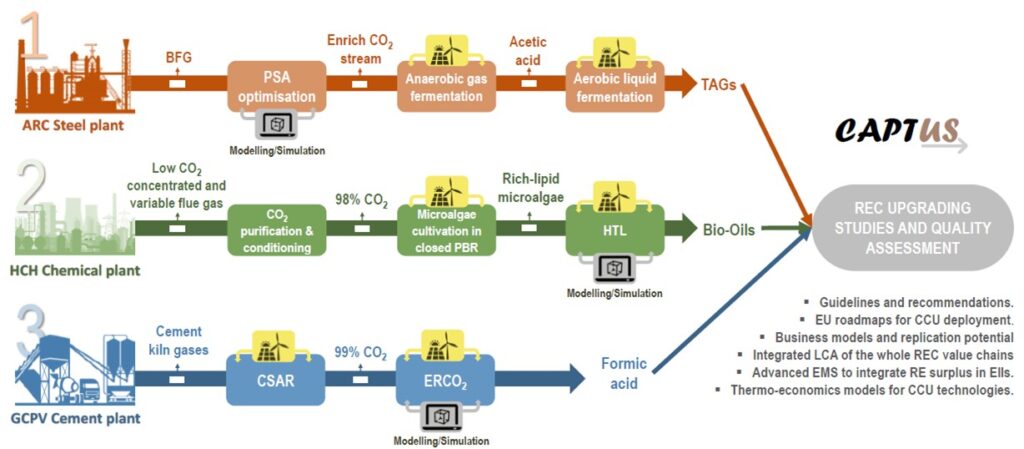

CAPTUS aims to demonstrate sustainable and cost-effective pathways to produce these high-added value renewable energy carriers (RECs) in EIIs by valorizing industrial carbon emissions and integrating renewable electricity surplus. Three complete REC value chains will be demonstrated at TRL7 at three different demonstration sites:

- Bioprocess based on a two-stage fermentation to produce triglycerides in a steel plant.

- Lipids-rich microalgae cultivation followed by hydrothermal liquefaction to produce bio-oils in a chemical plant.

- Electrochemical reduction of CO2 to produce formic acid in a cement plant.

The proposed technologies will be tested and endorsed from lab to pilot scale, and the obtained RECs will be validated by upgrading studies for the formulation of high-performance fuels. In addition to developing, engineering and implementing CCU technologies along the three demo-sites, CAPTUS will analyze the integration of the validated solutions in EIIs regarding economic, environmental, societal and geo-political criteria. By contributing with guidelines and strategies for decarbonization roadmap, CAPTUS will improve awareness and acceptance of CCU technologies and the obtained RECs, as well as construct suitable business cases.

ACTIVITIES of the Bio Base Europe Pilot Plant

BBEPP will be responsible for the first demonstration case through:

- Optimization of the gas-substrate fermentation process to convert CO2-rich PSA tail gas from the steel industry into acetic acid

- Optimization and piloting of the liquid-substrate fermentation process to convert acetic acid into triacylglycerides, ready for hydrotreatment towards biofuels

- Engineering and installation of a mobile fermentation plant at Arcelor Mittal’s facilities

- Scale-up and real demonstration of the fermentation process coupled to the downstream purification process

PARTNERS

- Fundación CIRCE, ES

- SINTEF, NO

- University of Cantabria, ES

- CSIC, ES

- University of Genova, IT

- Steinbeis Innovation, DE

- Centre for Research and Technology Hellas, GR

- Bio Base Europe Pilot Plant, BE

- Novis BioBased Technology, DE

- Apria Systems, ES

- DRAXIS Environmental, GR

- A4F – Alga Fuel SA, PT

- GOODFUELS, NL

- RINA Consulting, IT

- Arcelor Mittal Belgium, BE

- HYCHEM – Química Sustentável, PT

- Grupo Cementos Portland Valderrivas, ES

- Energy Efficiency in Industrial Processes, BE

SUPPORTED by:

This project has received funding from the European Union’s Horizon Europe Programme under Grant Agreement number: 101118265.

Other Project in the Spotlight

BIOCON-CO2

BIOtechnological processes based on microbial platforms for the CONversion of CO2 from iron&steel industry into commodities for chemicals and plastics

Read More

webdesign

webdesign