Low TRL projects? Yes, we do!

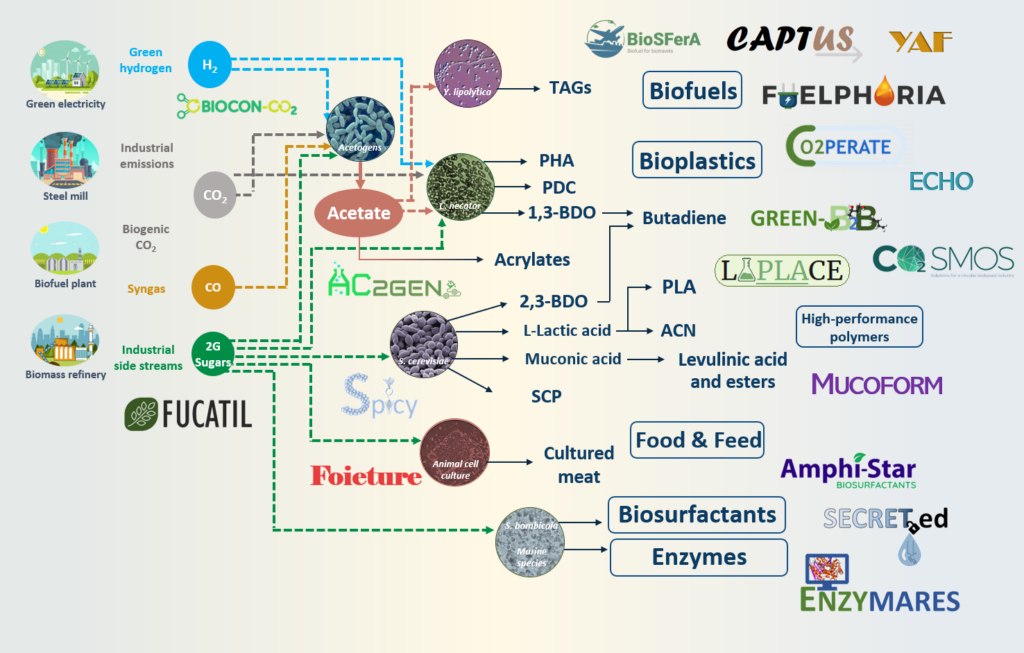

At Bio Base Europe Pilot Plant, different innovative technologies are being developed within the R&D Department to access a wide range of sustainable products from a variety of industrial feedstocks. These technologies are researched at low TRL (Technology Readiness Level) and include, amongst others, advanced fermentation and separation processes such as in situ product recovery to allow intensified production of important industrial platform molecules. BBEPP has also gained high expertise in biocatalysis and the production of novel recombinant proteins, as well as process intensification strategies such as continuous cultivation. Furthermore, BBEPP is a pioneer in the field of gas fermentation, where industrial CO2 emissions can be converted into a variety of valuable bioproducts such as biofuels, bioplastics and biomaterials. Finally, through the development of sustainable production strategies towards alternative proteins and cultured meat, BBEPP has been able to contribute to the global protein transition and the shift towards a more sustainable bioeconomy.

In July 2021, BBEPP announces the establishment of its first spin-off company: AmphiStar. AmphiStar is developing a proprietary technology platform for the ecological production of biosurfactants.

The figure below shows our R&D activities. More info on the projects mentioned in the figure below can be found on our “Consortium based projects” page or below the image.

Low TRL projects involving GAS FERMENTATION technology:

- BIOCONCO2: from CO2 from iron & steel industry to commodities for chemicals and plastics

- BioSFerA: From syngas fermentation to aviation and maritime biofuels

- CAPTUS: Demonstrating energy intensive industry-integrated solutions to produce liquid renewable energy carriers from captured carbon emissions

- CO2PERATE: All renewable CCU based on formic acid integrated in an industrial microgrid

- CO2SMOS: from biogenic CO2 emissions to advanced chemicals

- ECHO: Engineering Cupriavidus necator for the hydrogen-efficient production of a pyrone building block from industrial gas streams

- FUELPHORIA: Sustainable production of advanced biofuels and RFNBOs

Low TRL projects on the production of INDUSTRIAL PLATFORM CHEMICALS:

- AC2GEN: Acrylates from 2G sugars: a powerful combination of fermentation, catalysis, and CO2 recycling

- FUCATIL: Conversion of waste streams into platform chemicals using advanced separation and biocatalytic technologies

- GREEN-B2B and GREEN-B2B-2: Acid-catalyzed production of green butadiene from butanediols

- LAPLACE: Conversion of 2G wood side-streams into lactic acid and lactate esters as building blocks for biobased materials

- MUCOFORM: Synthesis and transformation of muconic acid into platform molecules starting from biomass

- SPICY: Sugar-based chemicals and polymers via chemocatalysis & engineered yeast

Low TRL projects producing BIOSURFACTANTS:

- SECRETed: Novel molecules by combining biosynthetic genes of amphiphilic compounds, biosurfactants and siderophores, produced by marine and extremophilic microorganisms

- Technology platform spinned out in first BBEPP spin-off: AmphiStar

AmphiStar is developing a proprietary technology platform for the ecological production of biosurfactants (amphiphilic molecules). The platform is initially based on the glycolipid technology platform with the yeast Starmerella bombicola, that has been developed and scaled up in over 10 years by Ghent University (InBio research group) and the Bio Base Europe Pilot Plant (BBEPP).

AmphiStar has the mission to develop, scale up and demonstrate biosurfactant technology at industrially relevant level.

webdesign

webdesign