CIRCular valorisation of industrial ALGAE waste streams into high-value products to foster future sustainable blue biorefineries in Europe

An innovative system to make the most out of algae

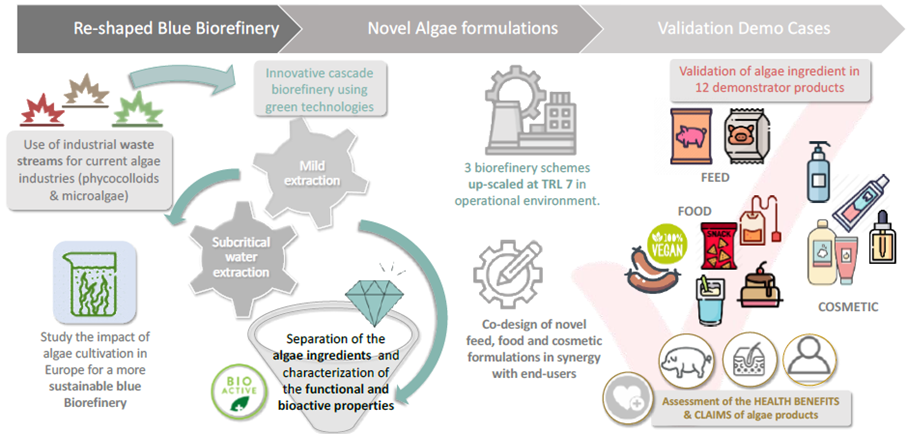

Algae biomass is highly underexploited and its efficient utilization is one of the main challenges in current and future EU marine policies towards sustainability. CIRCALGAE will boost the blue bioeconomy by applying an integrated biorefinery concept to valorise the massively produced (over 36 Mt of algae biomass annual world production) and vastly underexploited algae industrial waste streams (which can add up to 95% of the initial biomass) from the main existing sources to date: the phycolloid production from macroalgae and protein/lipid microalgae industries.

CIRCALGAE’s simple, water-based technologies, will transform these waste streams into value-added ingredients to be used in specific texturized vegan foods, health-promoting food ingredients, protein rich feed, and cosmetic formulations incorporating texturizing or highly bioactive ingredients for topical use. Three blue biorefinery schemes up-scaled to hundreds of kg will be demonstrated throughout the CIRCALGAE project. Twelve demonstrator products will be developed by food, feed and cosmetic industry partners validating the great potential of novel algae ingredients in these key sectors. Additionally, two final products will be qualified for market including their studies in consumer acceptance assessments.

Through co-creating and co–learning, CIRCALGAE will connect all algae cross-sectional actors, including industrial end-user partners, RTOs, technological and consultancy SMEs, for the validation of all health-promoting effects and claims, regulatory aspects and environmental, economic and social impacts, engaging all relevant stakeholders in the primary sector to re-shape the current industrial network for a future thriving blue bioeconomy.

ACTIVITIES of the Bio Base Europe Pilot Plant

Demo scale validation of the whole algae biorefinery concept (extraction and downstream processing of selected fractions) to demonstrate feasibility and deliver product for testing in industrial prototypes for food, feed, cosmetics and biomedical formulations.

PARTNERS

- KTH Royal Institute of Technology, SE (Coordinator)

- CSIC, ES

- IGV, DE

- MOREFORSKING AS, NO

- AQUIMER, FR

- Safe Food Advocacy Europe, BE

- A4F Algafuel SA, PT

- Bio Base Europe Pilot Plant, BE

- HISPANAGAR SA, ES

- Salata GmbH, DE

- Civitta Eesti AS, EE

- TEAGASC – Agriculture and Food Development Authority, IE

- ALGINOR ASA, NO

- Roquette Klötze GmbH & Co. KG, DE

- CEVA, Centre d’étude et de valorisation des algues SA, FR

- CEAMSA – Compania Espanola de Algas Marinas SA, ES

- NORDIC SEAFARM AB, SE

- NUTRITION SCIENCES, BE

- SAPONIA, HR

- Zeto ehf, IS

- RNB Cosmetics S.L, ES

SUPPORTED by:

This project has received funding from the European Union’s Horizon Europe Programme under Grant Agreement number: 101060607.

webdesign

webdesign