Full Carbon Utilization: Conversion of abundant Flemish waste streams into platform chemicals using advanced separation and catalytic technologies

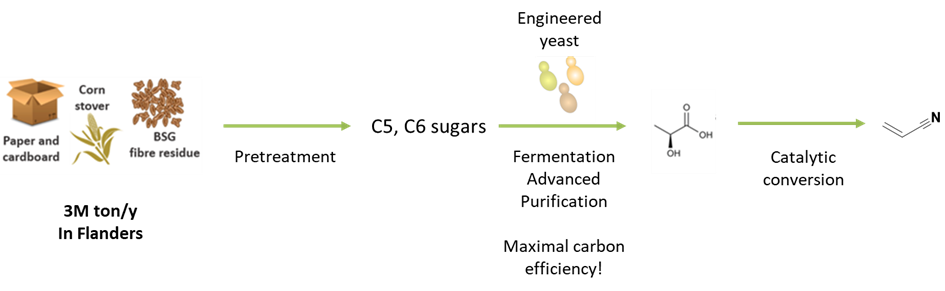

Through fermentation and catalysis, FUCATIL aims to convert undervalued Flemish waste streams into industrial chemical building blocks in a sustainable way. Every year, the disposal of old paper and cardboard, corn stover and brewer’s spent grain fibre residue in Flanders amounts to a combined total of 2.8 million tonnes of organic waste and a direct emission of nearly 2.3 Mtonnes of CO2. In fact, they are some of Flanders’ most abundant organic waste streams. They are also underutilized, exhibiting a clear potential to contribute to a more sustainable Flemish industry.

FUCATIL seeks to curtail emissions from organic waste streams by converting them into industrially relevant chemical building blocks by means of clean technologies. FUCATIL will integrate carbon-efficient fermentation processes with novel separation and catalytic conversion methods. The specific building block targeted is acrylonitrile, which is used to produce polymers for the automotive industry and carbon fibres. Currently these polymers are mainly produced from fossil feedstocks, resulting in limited yields and major CO2 emissions.

By developing sustainable and innovative organic waste-based production systems for acrylonitrile, FUCATIL will help Flemish industries step away from fossil-based production processes and significantly reduce their CO2 emissions.

ACTIVITIES of the Bio Base Europe Pilot Plant

- Finetuning and developing the enzymatic hydrolysis process on waste paper and cardboard in order to obtain C5 and C6 sugar hydrolysates

- Finetuning and developing the enzymatic hydrolysis process on RCF-pretreated (by partner KUL) corn stover and brewer’s spent grain fibre residue in order to obtain C5 and C6 sugar hydrolysates

- Development of the fermentation process towards an intermediate chemical building block using strains developed by partner VIB/KUL

- Development of an efficient in situ purification process for the extraction of an intermediate chemical building block from the fermentation broth. This building block will consequently be converted to acrylonitrile by partner KUL.

- Project coordinator

PARTNERS

- Bio Base Europe Pilot Plant, BE (Coordinator)

- Universiteit Gent, BE

- KU Leuven, BE

- Vlaams Insituut voor Biotechnologie (VIB), BE

SUPPORTED by

webdesign

webdesign