Filter on:

in situ product recovery- Feedstock

- End product

- Agriculture

- Bulk chemicals

- Enzymes

- Feed

- Food

- Antimicrobial peptides

- Arabinose

- Bakery products

- Cultured meat

- Fermented foods

- Flavour compounds

- Foie gras

- Food grade

- Food ingredients

- Fucosylated carbohydrates

- Halal & Kosher

- HMO

- Mixed starter culture

- Peptides

- Proteins

- Single cell protein

- Specialty carbohydrates

- Sugar monomers

- Sugars

- Triacylglycerides

- Vanillin

- Fuels

- Personal & home care

- Polymers, packaging & biomaterials

- Active barrier applications

- Active barrier coatings

- Automotive applications

- Biodegradable

- Bioester polyols

- Biomaterials

- Bioplastics

- Biopolymers

- BioPUR insulation

- Butadiene

- Carbon fibres

- Cellulose nanowhiskers

- Cement additives

- Chitin nanowhiskers

- Coating

- Construction materials

- Consumer goods

- FDCA

- Fibres

- Food and drink packaging

- Microcellulose fibers

- Nano additives

- PHA

- PHB

- PLA

- Polyamides

- Polycarbonate building blocks

- Polymers

- Polyols

- Super plasticizers

- Textile fibres

- TPU adhesives

- Wooden boards

- Xylan

- Specialty chemicals

- Technology

- TR Level

- Other project types

- Project status

- Funding tool and type

- Role

Running Projects

- AC2GEN

- Bio Base Advance

- Bio Base Demo

- Bio Base Flow

- Bio Base NextGen

- Bio Base Release

- Bio Base Transition

- BIOMAC

- Bionanopolys

- BioSFerA

- CAPTUS

- CIRCALGAE

- COMBO

- CO2SMOS

- ECHO

- ELLIPSE

- EnzyMares

- FUCATIL

- FUELPHORIA

- Glaukos

- Green-B2B-2

- HiPProFib

- HYBRID

- ICONIC

- LAPLACE

- LUCRA

- My-Fi

- Microbial Protein Transition

- MiProCas

- MUCOFORM

- Pilots4U powered by COPILOT

- REPurpose

- ROBOCOOP-EU

- SECRETed

- ShapingBio

- SYMBA

- UPLIFT

- WASTE2FUNC

- YAF

All Projects

AC2GEN

- (Inter)Cluster, 2G sugar, 2G sugar - agriculture, 2G sugar - industrial, Agricultural sidestreams, Biopolymers, Bulk chemicals, Carbon fibres, Chemical building blocks, Coating, Coordinator, Corn stover, DSP process development, Fermentation, In situ product recovery, Industrial sidestreams, Moonshot flanders-cSBO, Ongoing projects, Paper and cardboard, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, WP leader

Acrylates from 2nd generation sugars: a powerful combination of fermentation, catalysis, and CO2 recycling

Read More- (Inter)Cluster, 2G sugar, 2G sugar - agriculture, 2G sugar - industrial, Agricultural sidestreams, Biopolymers, Bulk chemicals, Carbon fibres, Chemical building blocks, Coating, Coordinator, Corn stover, DSP process development, Fermentation, In situ product recovery, Industrial sidestreams, Moonshot flanders-cSBO, Ongoing projects, Paper and cardboard, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, WP leader

FUCATIL

- (Inter)Cluster, 2G sugar, 2G sugar - agriculture, 2G sugar - industrial, Acrylic deratives, Agricultural sidestreams, Automotive, Biopolymers, Bulk chemicals, Carbon fibres, Chemical building blocks, Coordinator, Corn stover, DSP process development, Fermentation, In situ product recovery, Industrial sidestreams, Lactic acid, Moonshot flanders-cSBO, Ongoing projects, Paper and cardboard, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, WP leader

Full Carbon Utilization: Conversion of abundant Flemish waste streams into platform chemicals using advanced separation and catalytic technologies

Read More- (Inter)Cluster, 2G sugar, 2G sugar - agriculture, 2G sugar - industrial, Acrylic deratives, Agricultural sidestreams, Automotive, Biopolymers, Bulk chemicals, Carbon fibres, Chemical building blocks, Coordinator, Corn stover, DSP process development, Fermentation, In situ product recovery, Industrial sidestreams, Lactic acid, Moonshot flanders-cSBO, Ongoing projects, Paper and cardboard, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, WP leader

MUCOFORM

- 2G sugar, 2G sugar - industrial, Bulk chemicals, EU RRF project, Fermentation, Fwo, In situ product recovery, Industrial sidestreams, Low TRL, Muconic acid, Ongoing projects, Organic acids, Paper and cardboard, Partner, Product recovery and purification, Regional-flanders, Specialty chemicals, WP leader

Synthesis and transformation of muconic acid into platform molecules starting from biomass.

Read More- 2G sugar, 2G sugar - industrial, Bulk chemicals, EU RRF project, Fermentation, Fwo, In situ product recovery, Industrial sidestreams, Low TRL, Muconic acid, Ongoing projects, Organic acids, Paper and cardboard, Partner, Product recovery and purification, Regional-flanders, Specialty chemicals, WP leader

DemoProBio

- 1G sugar, AO-NIB, Aceton, Acetonitrile, Bulk chemicals, Butanol, Ethanol, Fermentation, Finished projects, Fuels, In situ product recovery, Product recovery & purification, Regional-flanders, Scale-up (TRL 4-6), Solvents, VLAIO/AO, WP leader

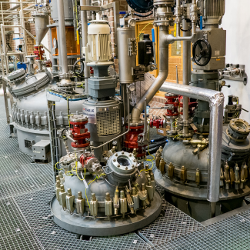

Industrial biotechnology plays a crucial role in the development of sustainable and cost effective production processes for biobased chemicals. These processes typically consist of two distinct unit operations: fermentation, followed by purification of the compound of interest from the fermentation broth. Product recovery and purification (also called downstream processing or DSP) are important cost factors, responsible for up to 80% of the total production cost. Reducing DSP cost is therefore a key success factor to improve the overall economics of biobased processes.

Read More- 1G sugar, AO-NIB, Aceton, Acetonitrile, Bulk chemicals, Butanol, Ethanol, Fermentation, Finished projects, Fuels, In situ product recovery, Product recovery & purification, Regional-flanders, Scale-up (TRL 4-6), Solvents, VLAIO/AO, WP leader

Ongoing projects

- AC2GEN

- Bio Base Advance

- Bio Base Demo

- Bio Base Flow

- Bio Base NextGen

- Bio Base Release

- Bio Base Transition

- BIOMAC

- Bionanopolys

- BioSFerA

- CAPTUS

- CIRCALGAE

- COMBO

- CO2SMOS

- ECHO

- ELLIPSE

- EnzyMares

- FUCATIL

- FUELPHORIA

- Glaukos

- Green-B2B-2

- HiPProFib

- HYBRID

- ICONIC

- LAPLACE

- LUCRA

- My-Fi

- Microbial Protein Transition

- MiProCas

- MUCOFORM

- Pilots4U powered by COPILOT

- REPurpose

- ROBOCOOP-EU

- SECRETed

- ShapingBio

- SYMBA

- UPLIFT

- WASTE2FUNC

- YAF

webdesign

webdesign