Recyclable Elastomeric Plastics safely and sUstainably designed and produced via enzymatic Recycling of Post-cOnsumer waSte strEams

Innovative recyclable elastomeric polymers from post-consumer waste recycling

The annual plastics production is expected to quadruple by 2050, making it essential to find new solutions for efficient use of resources for their production and keep the world’s consumption within its planetary boundaries. Commodity plastics will become part of the solution, provided they are collected and sorted appropriately and find their way back into new products. To reach higher levels of high-quality recycling and close the circular economy loop, design issues are increasingly addressed more systemically by integrating safety, circularity and functionality aspects from the early design stage to end of life.

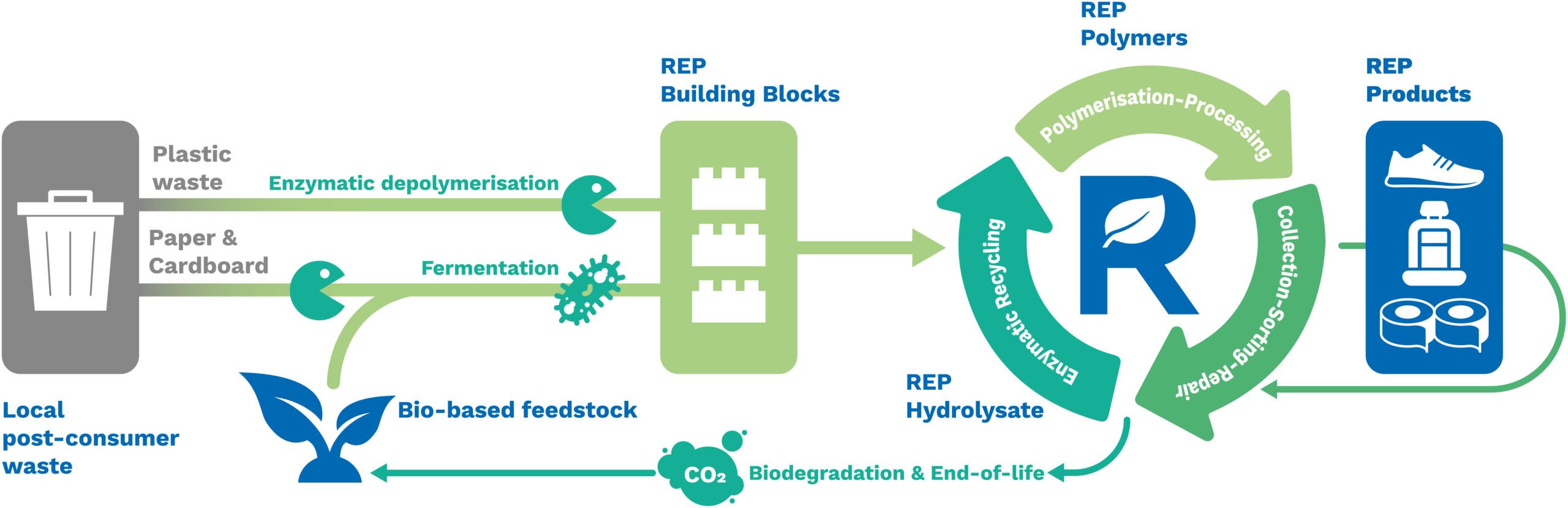

REPurpose will integrate this safety- and sustainability-by-design concept for the production of new bioplastics using a novel value-chain approach:

- Plastic waste as part of the solution – Targeted enzymatic conversion of local post-consumer waste streams to form building blocks for innovative plastics (‘repurposing of waste’). These are complemented with biobased building blocks.

- Safe- and sustainable-by-design plastics – Polymerisation of the building blocks into a platform of additive-free so-called ‘REP polymers’ with tuneable functional properties for high-value applications in the markets of rubbery materials (thermoplastic elastomers).

- First reuse, then effectively recycle and degrade – REP products will be reusable or repairable via controlled disassembly through ‘Design for Deconstruction’. REP polymers will be endlessly recyclable and even controlled biodegradable.

- Creating an enabling environment – To use a cross-sectorial value chain approach linking

- i) waste handlers, recyclers and detection experts;

- ii) regulatory framework advocates;

- iii) specialty building block producers;

- iv) technology developers for REP production and processing;

- and v) end users for consumer goods, building and construction products and automotive parts. A constant feedback loop will be established between the consortium and relevant stakeholders for successful industrial exploitation (End User Group).

ACTIVITIES of the Bio Base Europe Pilot Plant

- Project coordination and management

- Communication & Dissemination

- Set-up and coordination of End User Group and Advisory Board

- Production of enzymes for plastic waste depolymerisation: process development and scale-up to pilot scale

- Depolymerisation of commodity plastics into REP building blocks: process development and scale-up to pilot scale

- Process development and scale-up to pilot scale of fermentative production and purification of glutaric acid from paper & cardboard derived sugars, and cis,cis-muconic acid from lignin. The target compounds are further chemically converted into various C5- and C6-diacids and diols as REP building blocks

PARTNERS

- Bio Base Europe Pilot Plant, BE (Coordinator)

- B4Plastics, BE

- AIMPLAS, ES

- Renasci, BE

- Italbiotec, IT

- Saarland University, DE

- Photon Mission, NL

- University of Natural Resources and Life Sciences (BOKU), AT

- Aalborg University, DK

- Asociación Valenciana de Empresarios de Plásticos (AVEP), ES

- Epoch BioDesign, UK (Associated Partner)

MEMBERS of the REPurpose End User Group

SUPPORTED by:

This project has received funding from the European Union’s Horizon Europe Programme under Grant Agreement number: 101057971.

webdesign

webdesign