Novel, sustainable marine bio-surfactant/bio-emulsifier for commercial exploitation

Surfactants and emulsifiers are surface-active (SA) performance molecules used in a wide variety of applications in households, industry and agriculture. Industry is looking to replacing many of its synthetic SA ingredients, with more sustainable, natural and eco-friendly counterparts. Microbially-derived SAs offer a viable solution as they can be produced from renewable feedstock or waste streams and by natural fermentation processes. They are also readily biodegradable, display low eco-toxicity, and many can exhibit multiple levels of functionality which is a highly desirable trait for many industrial applications.

The MARISURF project will use marine bacterial strains to produce new SAs. To ensure the newly discovered SAs satisfy their requirements and demands, MARISURF will place the industrial end-users in a leading role in guiding the search for new SAs. End-users will be involved from the discovery stage on, all the way through the development pipeline to proof-of-concept and commercialisation.

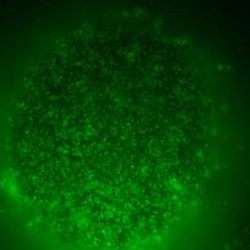

The MARISURF project is endowed with a unique collection of marine bacterial strains, housed by HWU (Lead partner), with proven potential for discovering new types of functional SAs. Importantly, some of the strains already screened (<5% of total strains in collection) have been shown to produce SAs with properties that the four industrial end-users of the consortium have identified as highly desirable in some of their applications, thus highlighting the enormous potential of this exploitable strain collection. An innovative screening programme will be used to focus the search on SAs exhibiting the types of characteristics the end-users demand.

The consortium includes experts from academia and the R&D sector with extensive expertise and experience in the optimisation of SA production by fermentation to generate sufficient material that will meet the demands of the industrial end-user partners.

ACTIVITIES of Bio Base Europe Pilot Plant

- Optimization of fermentation and production of SAs: shake-flask cultures, small scale fermenters (5-10L), pilot-scale level.

- Establish all aspects of the fermentation conditions and optimize the yields and productivities

- Develop the downstream processing

- Scale-up of the new fermentation processes so that sufficient SA material becomes available for various application tests by the Industrial end-users.

Interesting documents and links

PARTNERS

- Heriot-Watt University, UK

- University of Ulster, UK

- Macphie of Glenbervie ltd, UK

- Marlow foods, UK

- University of Patras, GR

- Democritus university of Thrace, GR

- Apivita kallyntika diaititika farmaka anonymi emporiki kai viotechniki etaireia, GR

- Bio Base Europe Pilot Plant vzw, BE

- Ecotechsystems srl, IT

- Acondicionamiento tarrassense association,ES

- Nanoimmunotech sl, ES

- Nova-Institut fur politische und okologische innovation gmbh, DE

SUPPORTED by:

Funded by the European Union Framework Programme for research and innovation, Horizon 2020 under grant agreement No 635340.

webdesign

webdesign