Filter on:

process development (TRL 4-5)- Feedstock

- End product

- Agriculture

- Bulk chemicals

- Enzymes

- Feed

- Food

- Antimicrobial peptides

- Arabinose

- Bakery products

- Cultured meat

- Fermented foods

- Flavour compounds

- Foie gras

- Food grade

- Food ingredients

- Fucosylated carbohydrates

- Halal & Kosher

- HMO

- Mixed starter culture

- Peptides

- Proteins

- Single cell protein

- Specialty carbohydrates

- Sugar monomers

- Sugars

- Triacylglycerides

- Vanillin

- Fuels

- Personal & home care

- Polymers, packaging & biomaterials

- Active barrier applications

- Active barrier coatings

- Automotive applications

- Biodegradable

- Bioester polyols

- Biomaterials

- Bioplastics

- Biopolymers

- BioPUR insulation

- Butadiene

- Carbon fibres

- Cellulose nanowhiskers

- Cement additives

- Chitin nanowhiskers

- Coating

- Construction materials

- Consumer goods

- FDCA

- Fibres

- Food and drink packaging

- Microcellulose fibers

- Nano additives

- PHA

- PHB

- PLA

- Polyamides

- Polycarbonate building blocks

- Polymers

- Polyols

- Super plasticizers

- Textile dyes

- Textile fibres

- TPU adhesives

- Wooden boards

- Xylan

- Specialty chemicals

- Technology

- TR Level

- Other project types

- Project status

- Funding tool and type

- Role

Running Projects

- AC2GEN

- Bio Base Advance

- Bioeconomy GIANTS

- BIOMAC

- BIOPYRANIA

- CAPTUS

- CIRCALGAE

- CIRCLE

- COMBO

- DyeAnotherWay

- ELLIPSE

- EnzyMares

- FERM eiwit

- Fibre Save

- FLEXIZYME

- FUELPHORIA

- Green-B2B-2

- HiPProFib

- HYBRID

- ICO2NIC

- ICONIC

- LAPLACE

- LUCRA

- NEXT-STEP

- Pilots4U powered by COPILOT

- POLYMEER

- PROMOFER

- REPurpose

- ROBOCOOP-EU

- SECRETed

- ShapingBio

- SOLRESS

- SUPROSEA

- SURFs UP

- SYMBA

- ToBeReal

- UPCYCLE

- YAF

- ZELDA

All Projects

Afterlife

- Aerobic fermentation, Anaerobic fermentation, Bioplastics, CAPEX, Circular Economy, Demonstration (TRL 5-7), Fermentation, H2020 BBI-RIA, Industrial sidestreams, LCA, Mixed culture, PHA, PHB, Passed projects, Polymers and packaging and biomaterials, Process development (TRL 4-5), Process waters, Product recovery and purification, Scale-up (TRL 4-6), WP leader

The AFTERLIFE project proposes a flexible, cost- and resource-efficient process for recovering and valorising the relevant fractions from wastewater.

Read More- Aerobic fermentation, Anaerobic fermentation, Bioplastics, CAPEX, Circular Economy, Demonstration (TRL 5-7), Fermentation, H2020 BBI-RIA, Industrial sidestreams, LCA, Mixed culture, PHA, PHB, Passed projects, Polymers and packaging and biomaterials, Process development (TRL 4-5), Process waters, Product recovery and purification, Scale-up (TRL 4-6), WP leader

Bio Base NextGen

- EU RRF project, Finished projects, Investment project, Process development (TRL 4-5), Regional-flanders, Scale-up (TRL 4-6), VLAIO/AO

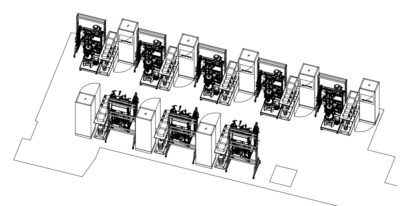

The Bio Base NextGen Fermentation Platform enables accelerated scale-up of innovative fermentation processes from lab scale to a relevant demonstration and production scale.

Read More- EU RRF project, Finished projects, Investment project, Process development (TRL 4-5), Regional-flanders, Scale-up (TRL 4-6), VLAIO/AO

BIOCON-CO2

- Acrylic deratives, Alcohols, Biocatalysis, Bioplastics, Biopolymers, Bulk chemicals, CCU, CO, CO2, Feed, Feed additives, Feed ingredients, Fermentation, Finished projects, Formic acid, Gas fermentation, Gasses, H2, H2020-RIA, Lactic acid, Mobile unit, PHA, PHB, Partner, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Scale-up (TRL 4-6), Specialty chemicals, Steel mill gasses, Waste gasses

BIOtechnological processes based on microbial platforms for the CONversion of CO2 from iron&steel industry into commodities for chemicals and plastics

Read More- Acrylic deratives, Alcohols, Biocatalysis, Bioplastics, Biopolymers, Bulk chemicals, CCU, CO, CO2, Feed, Feed additives, Feed ingredients, Fermentation, Finished projects, Formic acid, Gas fermentation, Gasses, H2, H2020-RIA, Lactic acid, Mobile unit, PHA, PHB, Partner, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Scale-up (TRL 4-6), Specialty chemicals, Steel mill gasses, Waste gasses

BIO-HArT

- Agricultural sidestreams, Aromatics, Biomass pretreatment, Carbohydrate extraction, Carbohydrates, Corn stover, Finished projects, Flax shives, Forestry sidestreams, Interreg VL-NL, Lignin, Lignin extraction, Miscanthus, Partner, Process development (TRL 4-5), Scale-up (TRL 4-6), Specialty chemicals

Biorizon has developed three commercially promising technologies for the conversion of wood, sugars and lignin into aromatics. By demonstrating the technology within this project on a larger scale, the confidence in the applicability of the technology on an industrial scale enhances and the risk to invest diminishes.

Read More- Agricultural sidestreams, Aromatics, Biomass pretreatment, Carbohydrate extraction, Carbohydrates, Corn stover, Finished projects, Flax shives, Forestry sidestreams, Interreg VL-NL, Lignin, Lignin extraction, Miscanthus, Partner, Process development (TRL 4-5), Scale-up (TRL 4-6), Specialty chemicals

BioRen

- 2G biomass, Advanced fuels, Biofuel, Bulk chemicals, Ethanol, Finished projects, Fuels, Glycerol tertiary butyl ether, H2020-RIA, Industrial sidestreams, Isobutanol, MSW, Municipal solid waste, Other feedstock, Paper & cardboard, Process development (TRL 4-5), Product recovery and purification, Scale-up, Scale-up (TRL 4-6), WP leader

The objective of BioRen is to develop competitive drop-in biofuels for road transport from the organic fraction of municipal solid waste (OFMSW). A higher value fuel is targeted: glycerol tertiary butyl ether (GTBE) is a promising fuel additive to both diesel and gasoline that improves engine performance and cuts harmful exhaust emissions (e.g. fine dust).

Read More- 2G biomass, Advanced fuels, Biofuel, Bulk chemicals, Ethanol, Finished projects, Fuels, Glycerol tertiary butyl ether, H2020-RIA, Industrial sidestreams, Isobutanol, MSW, Municipal solid waste, Other feedstock, Paper & cardboard, Process development (TRL 4-5), Product recovery and purification, Scale-up, Scale-up (TRL 4-6), WP leader

BioSFerA

- 2G biomass, CO, CO2, Fermentation, Finished projects, Food, Forestry waste, Fuels, Gas fermentation, Gasses, H2, H2020-RIA, Jet fuel, Marine fuel, Mobile unit, Partner, Process development (TRL 4-5), Product recovery and purification, Scale-up (TRL 4-6), Syngas, Triacylglycerides

BioSFerA aims to develop a cost-effective interdisciplinary technology to produce sustainable aviation and maritime fuels. Thus, biogenic residues and wastes will be gasified and the syngas will be fermented to produce bio-based triacylglycerides (TAGs).

Read More- 2G biomass, CO, CO2, Fermentation, Finished projects, Food, Forestry waste, Fuels, Gas fermentation, Gasses, H2, H2020-RIA, Jet fuel, Marine fuel, Mobile unit, Partner, Process development (TRL 4-5), Product recovery and purification, Scale-up (TRL 4-6), Syngas, Triacylglycerides

ChitoBioEngineering

- 1G sugar, Agriculture, Bacterial, Biopolymers, Chitin, Chito-oligosaccharides, Chitosans, Coordinator, E. coli, ERA-IB, Fermentation, Finished projects, Food related sidestreams, Glucose, Process development (TRL 4-5), Sucrose, Sugar, WP leader

The ChitoBioEngineering project aims at establishing biotechnological ways of producing fully defined, partially acetylated chitosan oligomers. This will be achieved through genetic, metabolic, and enzyme engineering.

Read More- 1G sugar, Agriculture, Bacterial, Biopolymers, Chitin, Chito-oligosaccharides, Chitosans, Coordinator, E. coli, ERA-IB, Fermentation, Finished projects, Food related sidestreams, Glucose, Process development (TRL 4-5), Sucrose, Sugar, WP leader

CO2PERATE

- (Inter)Cluster, Bioplastics, Biopolymers, CCU, CO2, Catalisti-ISBO, Feed, Fermentation, Finished projects, Food, Formic acid, Gas fermentation, Gasses, H2, Low TRL, Other feedstock, PHA, PHB, Partner, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, Single cell protein, Specialty chemicals, Waste gasses

CO2PERATE aims to develop catalytic technologies to convert CO2 into formic acid, using renewable electricity. Formic acid will subsequently be used as building block for the biosynthetic production of value-added chemicals, as a building block for the chemical industry, or as a potential carrier for energy storage.

Read More- (Inter)Cluster, Bioplastics, Biopolymers, CCU, CO2, Catalisti-ISBO, Feed, Fermentation, Finished projects, Food, Formic acid, Gas fermentation, Gasses, H2, Low TRL, Other feedstock, PHA, PHB, Partner, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, Single cell protein, Specialty chemicals, Waste gasses

CO2SMOS

- Bioplastics, Bulk chemicals, Butanediol, CO, CO2, Diols, Fermentation, Finished projects, Gas fermentation, Gasses, H2, H2020-RIA, PHA, PHB, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Specialty chemicals, Syngas, WP leader

CO2SMOS aims to develop a platform of technologies to transform CO2 emissions produced by bio-based industries into a set a of high added-value chemicals.

Read More- Bioplastics, Bulk chemicals, Butanediol, CO, CO2, Diols, Fermentation, Finished projects, Gas fermentation, Gasses, H2, H2020-RIA, PHA, PHB, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Specialty chemicals, Syngas, WP leader

Ongoing projects

- AC2GEN

- Bio Base Advance

- Bioeconomy GIANTS

- BIOMAC

- BIOPYRANIA

- CAPTUS

- CIRCALGAE

- CIRCLE

- COMBO

- DyeAnotherWay

- ELLIPSE

- EnzyMares

- FERM eiwit

- Fibre Save

- FLEXIZYME

- FUELPHORIA

- Green-B2B-2

- HiPProFib

- HYBRID

- ICO2NIC

- ICONIC

- LAPLACE

- LUCRA

- NEXT-STEP

- Pilots4U powered by COPILOT

- POLYMEER

- PROMOFER

- REPurpose

- ROBOCOOP-EU

- SECRETed

- ShapingBio

- SOLRESS

- SUPROSEA

- SURFs UP

- SYMBA

- ToBeReal

- UPCYCLE

- YAF

- ZELDA

webdesign

webdesign