Filter on:

Regional-Flanders- Feedstock

- End product

- Agriculture

- Bulk chemicals

- Enzymes

- Feed

- Food

- Antimicrobial peptides

- Arabinose

- Bakery products

- Cultured meat

- Fermented foods

- Flavour compounds

- Foie gras

- Food grade

- Food ingredients

- Fucosylated carbohydrates

- Halal & Kosher

- HMO

- Mixed starter culture

- Peptides

- Proteins

- Single cell protein

- Specialty carbohydrates

- Sugar monomers

- Sugars

- Triacylglycerides

- Vanillin

- Fuels

- Personal & home care

- Polymers, packaging & biomaterials

- Active barrier applications

- Active barrier coatings

- Automotive applications

- Biodegradable

- Bioester polyols

- Biomaterials

- Bioplastics

- Biopolymers

- BioPUR insulation

- Butadiene

- Carbon fibres

- Cellulose nanowhiskers

- Cement additives

- Chitin nanowhiskers

- Coating

- Construction materials

- Consumer goods

- FDCA

- Fibres

- Food and drink packaging

- Microcellulose fibers

- Nano additives

- PHA

- PHB

- PLA

- Polyamides

- Polycarbonate building blocks

- Polymers

- Polyols

- Super plasticizers

- Textile fibres

- TPU adhesives

- Wooden boards

- Xylan

- Specialty chemicals

- Technology

- TR Level

- Other project types

- Project status

- Funding tool and type

- Role

Running Projects

- AC2GEN

- Bio Base Advance

- Bio Base Demo

- Bio Base Flow

- Bio Base NextGen

- Bio Base Release

- Bio Base Transition

- BIOMAC

- Bionanopolys

- BioSFerA

- CAPTUS

- CIRCALGAE

- COMBO

- CO2SMOS

- ECHO

- ELLIPSE

- EnzyMares

- FUCATIL

- FUELPHORIA

- Glaukos

- Green-B2B-2

- HiPProFib

- HYBRID

- ICONIC

- LAPLACE

- LUCRA

- My-Fi

- Microbial Protein Transition

- MiProCas

- MUCOFORM

- Pilots4U powered by COPILOT

- REPurpose

- ROBOCOOP-EU

- SECRETed

- ShapingBio

- SYMBA

- UPLIFT

- WASTE2FUNC

- YAF

All Projects

AC2GEN

- (Inter)Cluster, 2G sugar, 2G sugar - agriculture, 2G sugar - industrial, Agricultural sidestreams, Biopolymers, Bulk chemicals, Carbon fibres, Chemical building blocks, Coating, Coordinator, Corn stover, DSP process development, Fermentation, In situ product recovery, Industrial sidestreams, Moonshot flanders-cSBO, Ongoing projects, Paper and cardboard, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, WP leader

Acrylates from 2nd generation sugars: a powerful combination of fermentation, catalysis, and CO2 recycling

Read More- (Inter)Cluster, 2G sugar, 2G sugar - agriculture, 2G sugar - industrial, Agricultural sidestreams, Biopolymers, Bulk chemicals, Carbon fibres, Chemical building blocks, Coating, Coordinator, Corn stover, DSP process development, Fermentation, In situ product recovery, Industrial sidestreams, Moonshot flanders-cSBO, Ongoing projects, Paper and cardboard, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, WP leader

Bio Base Advance

- Coordinator, EFRO/ERDF, Food, Investment project, Ongoing projects, Product recovery and purification, Proteins, Regional-flanders

Investment in equipment for the product recovery and purification of microbial protein, and infrastructure for local treatment of its process waters.

Read More- Coordinator, EFRO/ERDF, Food, Investment project, Ongoing projects, Product recovery and purification, Proteins, Regional-flanders

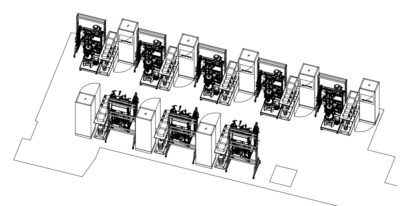

Bio Base Demo

- Demonstration (TRL 5-7), EU RRF project, Investment project, Regional-flanders, VLAIO/AO

Bio Base Europe Pilot Plant is building a fully equipped 75 m3 fermentation line.

Read More- Demonstration (TRL 5-7), EU RRF project, Investment project, Regional-flanders, VLAIO/AO

Bio Base Flow

- Coordinator, EFRO/ERDF, Investment project, Ongoing projects, Regional-flanders

Infrastructure for the support of the technology transfer between companies and the Bio Base Europe…

Read More- Coordinator, EFRO/ERDF, Investment project, Ongoing projects, Regional-flanders

Bio Base NextGen

- EU RRF project, Investment project, Process development (TRL 4-5), Regional-flanders, Scale-up (TRL 4-6), VLAIO/AO

The Bio Base NextGen Fermentation Platform enables accelerated scale-up of innovative fermentation processes from lab scale to a relevant demonstration and production scale.

Read More- EU RRF project, Investment project, Process development (TRL 4-5), Regional-flanders, Scale-up (TRL 4-6), VLAIO/AO

Bio Base Release

- Coordinator, EFRO/ERDF, Fermentation, Investment project, Ongoing projects, Product recovery and purification, Regional-flanders

Investment in additional process and analysis equipment to simplify and make fermentation and purification of intracellularly formed products more efficient.

Read More- Coordinator, EFRO/ERDF, Fermentation, Investment project, Ongoing projects, Product recovery and purification, Regional-flanders

Bio Base Transition

- Demonstration (TRL 5-7), Investment project, Regional-flanders, Scale-up (TRL 4-6), VLAIO/AO

The Bio Base Transition investment concerns a fermentation line (15m3) for demonstration of the valorisation of renewable raw materials, green methanol or waste materials into complex compounds, as an alternative to (petro)chemistry.

Read More- Demonstration (TRL 5-7), Investment project, Regional-flanders, Scale-up (TRL 4-6), VLAIO/AO

ECHO

- Biodegradable, Biopolymers, Bulk chemicals, CCU, CO2, Chemical building blocks, EU RRF project, Fermentation, Fwo, Gas fermentation, Gasses, H2, Low TRL, Ongoing projects, Partner, Polymers and packaging and biomaterials, Regional-flanders, WP leader, Waste gasses

Engineering Cupriavidus necator for the Hydrogen-efficient production of a pyrOne building block from industrial gas streams.

Read More- Biodegradable, Biopolymers, Bulk chemicals, CCU, CO2, Chemical building blocks, EU RRF project, Fermentation, Fwo, Gas fermentation, Gasses, H2, Low TRL, Ongoing projects, Partner, Polymers and packaging and biomaterials, Regional-flanders, WP leader, Waste gasses

EnzyMares

- (Inter)Cluster, Blauwe Cluster, Catalisti, Catalisti-SBO, Enzymes, Flanders Food, Low TRL, Ongoing projects, Regional-flanders, VLAIO/AO

Within EnzyMares, this multidisciplinary consortium develops a toolbox with which the specific characteristics of enzymes can be predicted on the basis of a multi-omics approach.

Read More- (Inter)Cluster, Blauwe Cluster, Catalisti, Catalisti-SBO, Enzymes, Flanders Food, Low TRL, Ongoing projects, Regional-flanders, VLAIO/AO

Ongoing projects

- AC2GEN

- Bio Base Advance

- Bio Base Demo

- Bio Base Flow

- Bio Base NextGen

- Bio Base Release

- Bio Base Transition

- BIOMAC

- Bionanopolys

- BioSFerA

- CAPTUS

- CIRCALGAE

- COMBO

- CO2SMOS

- ECHO

- ELLIPSE

- EnzyMares

- FUCATIL

- FUELPHORIA

- Glaukos

- Green-B2B-2

- HiPProFib

- HYBRID

- ICONIC

- LAPLACE

- LUCRA

- My-Fi

- Microbial Protein Transition

- MiProCas

- MUCOFORM

- Pilots4U powered by COPILOT

- REPurpose

- ROBOCOOP-EU

- SECRETed

- ShapingBio

- SYMBA

- UPLIFT

- WASTE2FUNC

- YAF

webdesign

webdesign