Filter on:

Process development (TRL 4-5)- Feedstock

- End product

- Agriculture

- Bulk chemicals

- Enzymes

- Feed

- Food

- Antimicrobial peptides

- Arabinose

- Bakery products

- Cultured meat

- Fermented foods

- Flavour compounds

- Foie gras

- Food grade

- Food ingredients

- Fucosylated carbohydrates

- Halal & Kosher

- HMO

- Mixed starter culture

- Peptides

- Proteins

- Single cell protein

- Specialty carbohydrates

- Sugar monomers

- Sugars

- Triacylglycerides

- Vanillin

- Fuels

- Personal & home care

- Polymers, packaging & biomaterials

- Active barrier applications

- Active barrier coatings

- Automotive applications

- Biodegradable

- Bioester polyols

- Biomaterials

- Bioplastics

- Biopolymers

- BioPUR insulation

- Butadiene

- Carbon fibres

- Cellulose nanowhiskers

- Cement additives

- Chitin nanowhiskers

- Coating

- Construction materials

- Consumer goods

- FDCA

- Fibres

- Food and drink packaging

- Microcellulose fibers

- Nano additives

- PHA

- PHB

- PLA

- Polyamides

- Polycarbonate building blocks

- Polymers

- Polyols

- Super plasticizers

- Textile fibres

- TPU adhesives

- Wooden boards

- Xylan

- Specialty chemicals

- Technology

- TR Level

- Other project types

- Project status

- Funding tool and type

- Role

Running Projects

- AC2GEN

- Bio Base Advance

- Bio Base Demo

- Bio Base Flow

- Bio Base NextGen

- Bio Base Release

- Bio Base Transition

- BIOMAC

- Bionanopolys

- BioSFerA

- CAPTUS

- CIRCALGAE

- COMBO

- CO2SMOS

- ECHO

- ELLIPSE

- EnzyMares

- FUCATIL

- FUELPHORIA

- Glaukos

- Green-B2B-2

- HiPProFib

- HYBRID

- ICONIC

- LAPLACE

- LUCRA

- My-Fi

- Microbial Protein Transition

- MiProCas

- MUCOFORM

- Pilots4U powered by COPILOT

- REPurpose

- ROBOCOOP-EU

- SECRETed

- ShapingBio

- SYMBA

- UPLIFT

- WASTE2FUNC

- YAF

All Projects

AC2GEN

- (Inter)Cluster, 2G sugar, 2G sugar - agriculture, 2G sugar - industrial, Agricultural sidestreams, Biopolymers, Bulk chemicals, Carbon fibres, Chemical building blocks, Coating, Coordinator, Corn stover, DSP process development, Fermentation, In situ product recovery, Industrial sidestreams, Moonshot flanders-cSBO, Ongoing projects, Paper and cardboard, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, WP leader

Acrylates from 2nd generation sugars: a powerful combination of fermentation, catalysis, and CO2 recycling

Read More- (Inter)Cluster, 2G sugar, 2G sugar - agriculture, 2G sugar - industrial, Agricultural sidestreams, Biopolymers, Bulk chemicals, Carbon fibres, Chemical building blocks, Coating, Coordinator, Corn stover, DSP process development, Fermentation, In situ product recovery, Industrial sidestreams, Moonshot flanders-cSBO, Ongoing projects, Paper and cardboard, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, WP leader

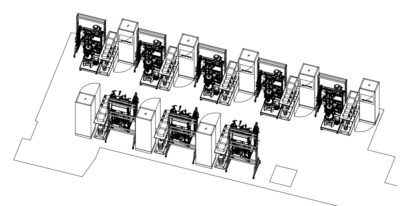

Bio Base NextGen

- EU RRF project, Investment project, Process development (TRL 4-5), Regional-flanders, Scale-up (TRL 4-6), VLAIO/AO

The Bio Base NextGen Fermentation Platform enables accelerated scale-up of innovative fermentation processes from lab scale to a relevant demonstration and production scale.

Read More- EU RRF project, Investment project, Process development (TRL 4-5), Regional-flanders, Scale-up (TRL 4-6), VLAIO/AO

BIOMAC

- Agricultural sidestreams, Biomass pretreatment, Cellulose diols, Corn stover, Diols, Food, Forestry sidestreams, Fractionation glucose, H2020-IA, Hemicellulose, Hydrolysis, Infrastructure, Infrastructure network, Innovation vouchers, Lignin, Lignin extraction, Lignocellulose, Low TRL, Miscanthus, Networking, Ongoing projects, Partner, Polymers and packaging and biomaterials, Polyols, Process development (TRL 4-5), Product recovery and purification, Specialty chemicals, Sugar alcohols, Sugar monomers, Value chain building, Xylose

The BIOMAC project aims to build a sustainable OITB (Open Innovation Test Bed), composed of 17 pilot plants and supported by several technical and non-technical services spread across Europe for the scale-up of new bio-based materials.

Read More- Agricultural sidestreams, Biomass pretreatment, Cellulose diols, Corn stover, Diols, Food, Forestry sidestreams, Fractionation glucose, H2020-IA, Hemicellulose, Hydrolysis, Infrastructure, Infrastructure network, Innovation vouchers, Lignin, Lignin extraction, Lignocellulose, Low TRL, Miscanthus, Networking, Ongoing projects, Partner, Polymers and packaging and biomaterials, Polyols, Process development (TRL 4-5), Product recovery and purification, Specialty chemicals, Sugar alcohols, Sugar monomers, Value chain building, Xylose

BioSFerA

- 2G biomass, CO, CO2, Fermentation, Food, Forestry waste, Fuels, Gas fermentation, Gasses, H2, H2020-RIA, Jet fuel, Marine fuel, Mobile unit, Ongoing projects, Partner, Process development (TRL 4-5), Product recovery and purification, Scale-up (TRL 4-6), Syngas, Triacylglycerides

BioSFerA aims to develop a cost-effective interdisciplinary technology to produce sustainable aviation and maritime fuels. Thus, biogenic residues and wastes will be gasified and the syngas will be fermented to produce bio-based triacylglycerides (TAGs).

Read More- 2G biomass, CO, CO2, Fermentation, Food, Forestry waste, Fuels, Gas fermentation, Gasses, H2, H2020-RIA, Jet fuel, Marine fuel, Mobile unit, Ongoing projects, Partner, Process development (TRL 4-5), Product recovery and purification, Scale-up (TRL 4-6), Syngas, Triacylglycerides

BioRen

- 2G biomass, Advanced fuels, Biofuel, Bulk chemicals, Ethanol, Finished projects, Fuels, Glycerol tertiary butyl ether, H2020-RIA, Industrial sidestreams, Isobutanol, MSW, Municipal solid waste, Other feedstock, Paper & cardboard, Process development (TRL 4-5), Product recovery and purification, Scale-up, Scale-up (TRL 4-6), WP leader

The objective of BioRen is to develop competitive drop-in biofuels for road transport from the organic fraction of municipal solid waste (OFMSW). A higher value fuel is targeted: glycerol tertiary butyl ether (GTBE) is a promising fuel additive to both diesel and gasoline that improves engine performance and cuts harmful exhaust emissions (e.g. fine dust).

Read More- 2G biomass, Advanced fuels, Biofuel, Bulk chemicals, Ethanol, Finished projects, Fuels, Glycerol tertiary butyl ether, H2020-RIA, Industrial sidestreams, Isobutanol, MSW, Municipal solid waste, Other feedstock, Paper & cardboard, Process development (TRL 4-5), Product recovery and purification, Scale-up, Scale-up (TRL 4-6), WP leader

CAPTUS

- Bulk chemicals, CCU, CO2, Chemical building blocks, Demonstration (TRL 5-7), Fermentation, Fuels, Gas fermentation, Gasses, H2, HEurope-IA, HEurope-Other, Jet fuel, Marine fuel, Ongoing projects, Process development (TRL 4-5), Product recovery and purification, Scale-up (TRL 4-6), Steel mill gasses, WP leader

CAPTUS will demonstrate three complete renewable energy carrier value chains at TRL7 at three different demonstration sites.

Read More- Bulk chemicals, CCU, CO2, Chemical building blocks, Demonstration (TRL 5-7), Fermentation, Fuels, Gas fermentation, Gasses, H2, HEurope-IA, HEurope-Other, Jet fuel, Marine fuel, Ongoing projects, Process development (TRL 4-5), Product recovery and purification, Scale-up (TRL 4-6), Steel mill gasses, WP leader

CO2SMOS

- Bioplastics, Bulk chemicals, Butanediol, CO, CO2, Diols, Fermentation, Gas fermentation, Gasses, H2, H2020-RIA, Ongoing projects, PHA, PHB, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Specialty chemicals, Syngas, WP leader

CO2SMOS aims to develop a platform of technologies to transform CO2 emissions produced by bio-based industries into a set a of high added-value chemicals.

Read More- Bioplastics, Bulk chemicals, Butanediol, CO, CO2, Diols, Fermentation, Gas fermentation, Gasses, H2, H2020-RIA, Ongoing projects, PHA, PHB, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Specialty chemicals, Syngas, WP leader

FUCATIL

- (Inter)Cluster, 2G sugar, 2G sugar - agriculture, 2G sugar - industrial, Acrylic deratives, Agricultural sidestreams, Automotive, Biopolymers, Bulk chemicals, Carbon fibres, Chemical building blocks, Coordinator, Corn stover, DSP process development, Fermentation, In situ product recovery, Industrial sidestreams, Lactic acid, Moonshot flanders-cSBO, Ongoing projects, Paper and cardboard, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, WP leader

Full Carbon Utilization: Conversion of abundant Flemish waste streams into platform chemicals using advanced separation and catalytic technologies

Read More- (Inter)Cluster, 2G sugar, 2G sugar - agriculture, 2G sugar - industrial, Acrylic deratives, Agricultural sidestreams, Automotive, Biopolymers, Bulk chemicals, Carbon fibres, Chemical building blocks, Coordinator, Corn stover, DSP process development, Fermentation, In situ product recovery, Industrial sidestreams, Lactic acid, Moonshot flanders-cSBO, Ongoing projects, Paper and cardboard, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, WP leader

FUELPHORIA

- Advanced fuels, Bulk chemicals, CCU, CO2, Chemical building blocks, Demonstration (TRL 5-7), Fermentation, Fuels, Gas fermentation, Gasses, H2, HEurope-IA, HEurope-Other, Jet fuel, Marine fuel, Ongoing projects, Process development (TRL 4-5), Product recovery and purification, Scale-up (TRL 4-6), WP leader, Waste gasses

FUELPHORIA will demonstrate successful and sustainable complete value chains for advanced biofuels and RFNBOs.

Read More- Advanced fuels, Bulk chemicals, CCU, CO2, Chemical building blocks, Demonstration (TRL 5-7), Fermentation, Fuels, Gas fermentation, Gasses, H2, HEurope-IA, HEurope-Other, Jet fuel, Marine fuel, Ongoing projects, Process development (TRL 4-5), Product recovery and purification, Scale-up (TRL 4-6), WP leader, Waste gasses

Ongoing projects

- AC2GEN

- Bio Base Advance

- Bio Base Demo

- Bio Base Flow

- Bio Base NextGen

- Bio Base Release

- Bio Base Transition

- BIOMAC

- Bionanopolys

- BioSFerA

- CAPTUS

- CIRCALGAE

- COMBO

- CO2SMOS

- ECHO

- ELLIPSE

- EnzyMares

- FUCATIL

- FUELPHORIA

- Glaukos

- Green-B2B-2

- HiPProFib

- HYBRID

- ICONIC

- LAPLACE

- LUCRA

- My-Fi

- Microbial Protein Transition

- MiProCas

- MUCOFORM

- Pilots4U powered by COPILOT

- REPurpose

- ROBOCOOP-EU

- SECRETed

- ShapingBio

- SYMBA

- UPLIFT

- WASTE2FUNC

- YAF

webdesign

webdesign