Filter on:

finished projects- Feedstock

- End product

- Agriculture

- Bulk chemicals

- Enzymes

- Feed

- Food

- Antimicrobial peptides

- Arabinose

- Bakery products

- Cultured meat

- Fermented foods

- Flavour compounds

- Foie gras

- Food grade

- Food ingredients

- Fucosylated carbohydrates

- Halal & Kosher

- HMO

- Mixed starter culture

- Peptides

- Proteins

- Single cell protein

- Specialty carbohydrates

- Sugar monomers

- Sugars

- Triacylglycerides

- Vanillin

- Fuels

- Personal & home care

- Polymers, packaging & biomaterials

- Active barrier applications

- Active barrier coatings

- Automotive applications

- Biodegradable

- Bioester polyols

- Biomaterials

- Bioplastics

- Biopolymers

- BioPUR insulation

- Butadiene

- Carbon fibres

- Cellulose nanowhiskers

- Cement additives

- Chitin nanowhiskers

- Coating

- Construction materials

- Consumer goods

- FDCA

- Fibres

- Food and drink packaging

- Microcellulose fibers

- Nano additives

- PHA

- PHB

- PLA

- Polyamides

- Polycarbonate building blocks

- Polymers

- Polyols

- Super plasticizers

- Textile dyes

- Textile fibres

- TPU adhesives

- Wooden boards

- Xylan

- Specialty chemicals

- Technology

- TR Level

- Other project types

- Project status

- Funding tool and type

- Role

Running Projects

- AC2GEN

- Bio Base Advance

- Bioeconomy GIANTS

- BIOMAC

- BIOPYRANIA

- CAPTUS

- CIRCALGAE

- CIRCLE

- COMBO

- DyeAnotherWay

- ELLIPSE

- EnzyMares

- FERM eiwit

- Fibre Save

- FLEXIZYME

- FUELPHORIA

- Green-B2B-2

- HiPProFib

- HYBRID

- ICO2NIC

- ICONIC

- LAPLACE

- LUCRA

- NEXT-STEP

- Pilots4U powered by COPILOT

- POLYMEER

- PROMOFER

- REPurpose

- ROBOCOOP-EU

- SECRETed

- ShapingBio

- SOLRESS

- SUPROSEA

- SURFs UP

- SYMBA

- ToBeReal

- UPCYCLE

- YAF

- ZELDA

All Projects

ChitoBioEngineering

- 1G sugar, Agriculture, Bacterial, Biopolymers, Chitin, Chito-oligosaccharides, Chitosans, Coordinator, E. coli, ERA-IB, Fermentation, Finished projects, Food related sidestreams, Glucose, Process development (TRL 4-5), Sucrose, Sugar, WP leader

The ChitoBioEngineering project aims at establishing biotechnological ways of producing fully defined, partially acetylated chitosan oligomers. This will be achieved through genetic, metabolic, and enzyme engineering.

Read More- 1G sugar, Agriculture, Bacterial, Biopolymers, Chitin, Chito-oligosaccharides, Chitosans, Coordinator, E. coli, ERA-IB, Fermentation, Finished projects, Food related sidestreams, Glucose, Process development (TRL 4-5), Sucrose, Sugar, WP leader

CLEO

- Det Energiteknologiske Udviklings- og Demonstrations program, Finished projects, Forestry sidestreams, Fuels, Lignin biomass, Lignin-based fuel, Marine fuel, Process development, Scale-up (TRL 4-6), WP leader

Sustainable and competitive lignin-based biofuels with sufficient supply-chain security and cost-efficiency to be used as a replacement of fossil-based oils in the marine sector.

Read More- Det Energiteknologiske Udviklings- og Demonstrations program, Finished projects, Forestry sidestreams, Fuels, Lignin biomass, Lignin-based fuel, Marine fuel, Process development, Scale-up (TRL 4-6), WP leader

CO2PERATE

- (Inter)Cluster, Bioplastics, Biopolymers, CCU, CO2, Catalisti-ISBO, Feed, Fermentation, Finished projects, Food, Formic acid, Gas fermentation, Gasses, H2, Low TRL, Other feedstock, PHA, PHB, Partner, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, Single cell protein, Specialty chemicals, Waste gasses

CO2PERATE aims to develop catalytic technologies to convert CO2 into formic acid, using renewable electricity. Formic acid will subsequently be used as building block for the biosynthetic production of value-added chemicals, as a building block for the chemical industry, or as a potential carrier for energy storage.

Read More- (Inter)Cluster, Bioplastics, Biopolymers, CCU, CO2, Catalisti-ISBO, Feed, Fermentation, Finished projects, Food, Formic acid, Gas fermentation, Gasses, H2, Low TRL, Other feedstock, PHA, PHB, Partner, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Regional-flanders, Single cell protein, Specialty chemicals, Waste gasses

CO2SMOS

- Bioplastics, Bulk chemicals, Butanediol, CO, CO2, Diols, Fermentation, Finished projects, Gas fermentation, Gasses, H2, H2020-RIA, PHA, PHB, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Specialty chemicals, Syngas, WP leader

CO2SMOS aims to develop a platform of technologies to transform CO2 emissions produced by bio-based industries into a set a of high added-value chemicals.

Read More- Bioplastics, Bulk chemicals, Butanediol, CO, CO2, Diols, Fermentation, Finished projects, Gas fermentation, Gasses, H2, H2020-RIA, PHA, PHB, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery and purification, Specialty chemicals, Syngas, WP leader

DAFIA

- Active barrier coatings, Biochemicals, Biopolymers, Bulk chemicals, Chemical building blocks, Di-amines, Fermentation, Finished projects, Flame retardants, Food related sidestreams, H2020-RIA, MSW, Marine waste, Muconic acid, Municipal solid waste, Other feedstock, Polyamides, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery & purification, Scale-up (TRL 4-6), Specialty chemicals, WP leader

The main objective of DAFIA is to exploit the organic fraction of municipal solid wastes (MSW) and marine rest raw materials (MRRM) as feedstocks for higher value products.

Read More- Active barrier coatings, Biochemicals, Biopolymers, Bulk chemicals, Chemical building blocks, Di-amines, Fermentation, Finished projects, Flame retardants, Food related sidestreams, H2020-RIA, MSW, Marine waste, Muconic acid, Municipal solid waste, Other feedstock, Polyamides, Polymers and packaging and biomaterials, Process development (TRL 4-5), Product recovery & purification, Scale-up (TRL 4-6), Specialty chemicals, WP leader

DEMETER

- 1G sugar, 2G sugar, 2G sugar - agriculture, Agricultural sidestreams, Agricultural waste, Anaerobic digestion, Biogas, Carbohydrates, Custom manufacturing, Demonstration (TRL 5-7), Enzyme formulation, Enzyme production, Enzymes, Fermentation, Finished projects, Formulation, Fuels, H2020 BBI-IA-DEMO, Product recovery & purification, Scale-up, Scale-up (TRL 4-6), WP leader

Demeter: Demonstrating more efficient enzyme production to increase biogas yields.

DEMETER will increase the yield of the fermentation process at an industrial scale as well as the down-stream processing of a C1-based biogas enzyme, reducing the cost of the end product and making the enzyme available for wide-spread application in biogas production throughout Europe.

- 1G sugar, 2G sugar, 2G sugar - agriculture, Agricultural sidestreams, Agricultural waste, Anaerobic digestion, Biogas, Carbohydrates, Custom manufacturing, Demonstration (TRL 5-7), Enzyme formulation, Enzyme production, Enzymes, Fermentation, Finished projects, Formulation, Fuels, H2020 BBI-IA-DEMO, Product recovery & purification, Scale-up, Scale-up (TRL 4-6), WP leader

DemoProBio

- 1G sugar, AO-NIB, Aceton, Acetonitrile, Bulk chemicals, Butanol, Ethanol, Fermentation, Finished projects, Fuels, In situ product recovery, Product recovery & purification, Regional-flanders, Scale-up (TRL 4-6), Solvents, VLAIO/AO, WP leader

Industrial biotechnology plays a crucial role in the development of sustainable and cost effective production processes for biobased chemicals. These processes typically consist of two distinct unit operations: fermentation, followed by purification of the compound of interest from the fermentation broth. Product recovery and purification (also called downstream processing or DSP) are important cost factors, responsible for up to 80% of the total production cost. Reducing DSP cost is therefore a key success factor to improve the overall economics of biobased processes.

Read More- 1G sugar, AO-NIB, Aceton, Acetonitrile, Bulk chemicals, Butanol, Ethanol, Fermentation, Finished projects, Fuels, In situ product recovery, Product recovery & purification, Regional-flanders, Scale-up (TRL 4-6), Solvents, VLAIO/AO, WP leader

ECHO

- Biodegradable, Biopolymers, Bulk chemicals, CCU, CO2, Chemical building blocks, EU RRF project, Fermentation, Finished projects, Fwo, Gas fermentation, Gasses, H2, Low TRL, Partner, Polymers and packaging and biomaterials, Regional-flanders, WP leader, Waste gasses

Engineering Cupriavidus necator for the Hydrogen-efficient production of a pyrOne building block from industrial gas streams.

Read More- Biodegradable, Biopolymers, Bulk chemicals, CCU, CO2, Chemical building blocks, EU RRF project, Fermentation, Finished projects, Fwo, Gas fermentation, Gasses, H2, Low TRL, Partner, Polymers and packaging and biomaterials, Regional-flanders, WP leader, Waste gasses

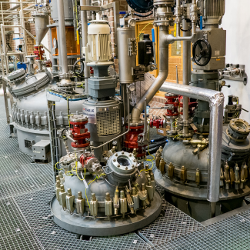

EFRO: Demonstration Equipment for Industrial Biotechnology

- Coordinator, Custom manufacturing, Demonstration (TRL 5-7), EFRO/ERDF, Fermentation, Finished projects, Industrial biotechnology, Infrastructure, Innovation, Investment project, SME support, Scale-up (TRL 4-6), WP leader

Europe, Flanders and the Province of East-Flanders invest €1,27 million in new equipment for Bio Base Europe Pilot Plant. These funds were used to purchase and install three new bioreactors with auxiliary equipment and software: two with a volume of 1.500L and one with a volume of 15.000L.

Read More- Coordinator, Custom manufacturing, Demonstration (TRL 5-7), EFRO/ERDF, Fermentation, Finished projects, Industrial biotechnology, Infrastructure, Innovation, Investment project, SME support, Scale-up (TRL 4-6), WP leader

Ongoing projects

- AC2GEN

- Bio Base Advance

- Bioeconomy GIANTS

- BIOMAC

- BIOPYRANIA

- CAPTUS

- CIRCALGAE

- CIRCLE

- COMBO

- DyeAnotherWay

- ELLIPSE

- EnzyMares

- FERM eiwit

- Fibre Save

- FLEXIZYME

- FUELPHORIA

- Green-B2B-2

- HiPProFib

- HYBRID

- ICO2NIC

- ICONIC

- LAPLACE

- LUCRA

- NEXT-STEP

- Pilots4U powered by COPILOT

- POLYMEER

- PROMOFER

- REPurpose

- ROBOCOOP-EU

- SECRETed

- ShapingBio

- SOLRESS

- SUPROSEA

- SURFs UP

- SYMBA

- ToBeReal

- UPCYCLE

- YAF

- ZELDA

webdesign

webdesign